Metal fabrication has been in existence for a very long time. In the Iron Age, blacksmiths used raw iron to fabricate farming tools and weapons. However, as times progressed, better fabrication methods were developed, particularly during the age of the industrial revolution. Readout below to know about metalwork stamping and forming.

Among the techniques developed, stamping is a method that people still use to date. It uses a cold forming principle to create desired shapes, designs, and patterns. This article aims at describing the processes which a metal stamping and forming Company undertakes to produce various metal components. We will also discuss the benefits of stamping over other methods of fabrication.

Table of Contents

What is Metalwork Stamping?

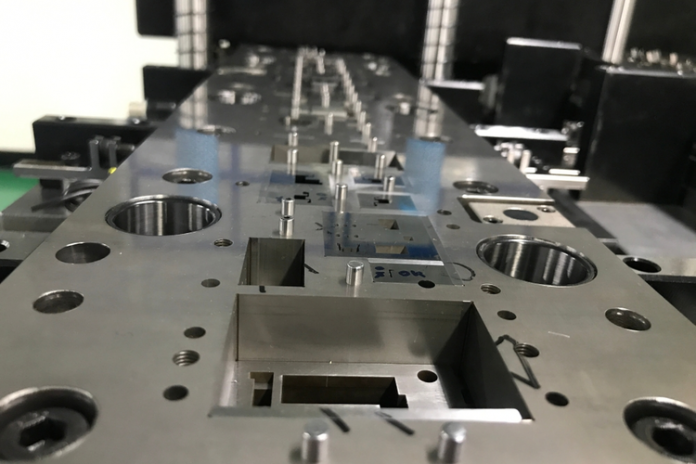

It refers to a high-speed, low-cost process of manufacturing identical metal parts in high volumes. It is also known as pressing. The operation is ideal for both long and short production runs. You can also perform stamping alongside other forming operations.

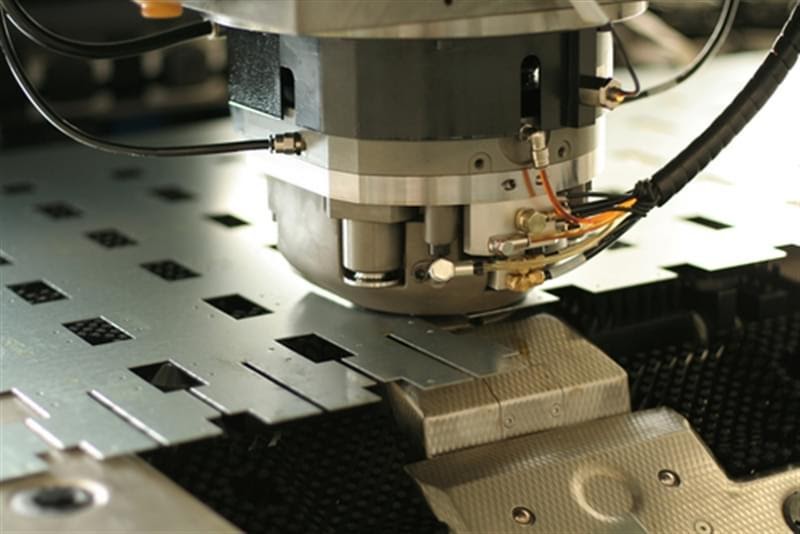

When performing this operation, you need a raw material, which is called blank material. It is placed in a machine containing presses and dies that are built in an organized form. The dies will push back on the raw material, subjecting it to compression for a period in order to give it the desired design.

Before now, the process was done manually because there were no advanced machines. As a result, manufacturers could only churn out simple parts such as bicycle frames. But with the advancement in technology, various processes are now automated. You can use computerized equipment to make better designs and at a quicker pace.

The Processes of Metalwork Stamping and Forming

The processes or techniques involved are:

Blanking and Punching

This technique uses dies to cut metals into specific shapes. During punching operations, scrap metals are removed, leaving holes in the workpieces. Blanking removes workpieces from their primary materials in order to make the removed components blank or the desired workpieces.

Embossing

This process creates recessed or raised designs in sheet metals. You can press raw blanks against dies containing the desired shapes to achieve embossment. Or you can pass the blank materials through roller dies.

Coining

This technique involves forming a workpiece while it is between a punch and a die. The tip of the punch will penetrate the workpiece, resulting in precise, repeatable bends. Also, the deep punch relieves internal stress in the workpiece to prevent a spring-back effect.

Bending

When forming metals into specific shapes like V, L, or U-shaped profiles, the bending technique is employed. The process results in plastic deformations that stress the upper yield point and the lower tensile strength. It usually occurs around a particular axis. You can read this article to understand the steps involved in metalwork stamping.

Factors to Consider When Choosing Materials for Metalwork Stamping and Forming

Stamping is more than just fabrication processes for metals. There are various materials that you can process using other techniques like rubber, paper, and leather. However, metal is more common, and your choice of metalwork material depends on your desired finished piece.

Generally, metals are ductile and malleable after forming. As a result, if you choose to carry out precision stamping, the metal must range between medium to soft hardness. It must also have a low flow coefficient. Some customary metal types that you can fabricate through forming are:

- Alloys, such as beryllium copper and beryllium nickel, that are non-standard.

- Metals, such as zinc, bronze, and brass, that are non-ferrous.

- Ferrous metals, particularly alloys with an iron base such as stainless steel.

- Precious metals like gold, platinum, and silver.

People tend to use more ferrous metals during stamping operations because they contain low carbon. Also, they are very cheap compared to other options. As a result, the production costs are greatly reduced.

Advantages of Metalwork Stamping

Metalwork stamping offers several benefits such as follows:

- You can easily automate the machine and use an advanced computer-controlled program to achieve more precision, faster turnaround times, and faster production. This automation further reduces labor costs, making the entire process cheaper.

- The dies for the operation are cheaper to manufacture and maintain compared to those employed in other fabrication methods.

- Secondary costs like plating and cleaning are cheaper than other forms of treatment required during metalwork fabrication.

- The technique uses cold forming methods instead of heat, which reduces the energy spent on manufacturing metal components. Hence, it is a cost-effective method.

Disadvantages of Metalwork Stamping

The drawbacks of this technique are:

- Although the technique is cost-effective, the press is quite expensive.

- You need to create or acquire the dies and manufacturing custom dies takes time. This can make the pre-production period longer.

- Once you create the custom dies, you cannot change the design when production is ongoing.

Some Applications of Stamping in Metalwork

You can apply the technique in various ways, especially on designs involving three dimensions, surface engraving components, or lettering. Such stamped items are commonly manufactured for electronic companies, lighting industries, telecommunication services, medical equipment producers, aerospace industries, military and defense, automotive companies, and manufacturers of home appliances.

You probably have an item in your house that has components produced through metalwork stamping. The technique is used to make everything from cars to household appliances. The specific components and products may range from complex designs like those in friction plates or engine bases to simple items like brackets, washers, weights, springs, and metal clips.

Metalwork stamping can be applied in the production of incredibly small, detailed parts as well as large machinery parts. You can use micro-precision to create parts that have diameters of about 0.002”. Additionally, electronic components use electronic stampings to manufacture parts for the aerospace, telecommunication, appliances, and home electronics industries.

These electronic stampings come in different metal types like steel, aluminum, copper alloys, and copper, including very expensive metals like gold and platinum. You can also use nonferrous and ferrous materials. The electronic components that you can produce with this method are pins, springs, lead frames, contacts, and terminals.

Conclusion

There are different techniques that you can use in metal fabrication, but stamping is ideal because it is cost-effective and produces high-quality results. You can also automate the process. We hope that you now understand the technique discussed in this article as well as the different areas of application. This will help you to make an informed decision when you plan to carry out your next metalwork project.

![How to Unlock Bootloader without PC On Android [2022]](https://cracktech.net/wp-content/uploads/2019/02/unlock-boot.png)